Description

MOBA GS-506 2D system

High performance grade and slope control

As a 2D levelling system, the GS-506 offers precise and reliable height and slope control and a high level of flexibility in the choice of sensors and fields of application. The increased productivity ensures that all levelling is performed faster and more accurately. This system saves time and money as its height accuracy eliminates the need for staking out and for correction works. Increase the productivity of your grader with MOBA’s GS-506 machine control system.

Features

- Precise height and slope control

- Wide variety of sensors

- Flexible sensor combination

- Works with reference

- Easy to use

System Benefits

- High precision

- Free mobility in difficult terrain

- Flexible fields of application

- Increases the efficiency and work speed

- Higher work quality

- Easily upgraded to 3D

GS-506 SYSTEM COMPONENTS

GS-506 Operating Control Panel

Control panel – all control information and current work status for the operator is always visible. The operator can also enter corrections, bring up system information, or change central settings Easy to operate Clear indication of all connected sensors.

- Clear, visual icon driven instructions

- LED status indicators

- Backlit keypad

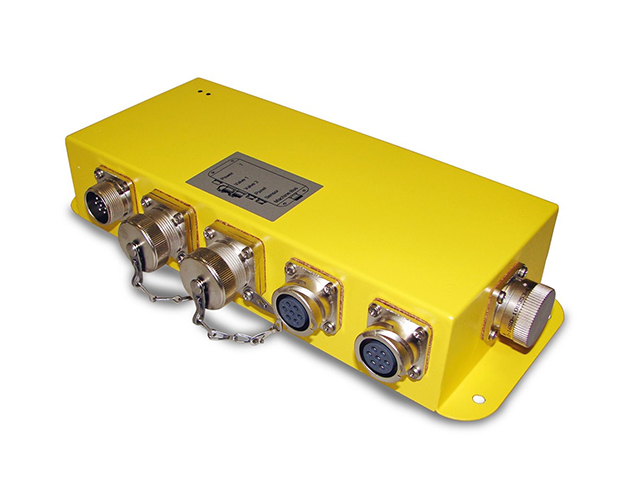

Controller

Receives and compares set target values with data continuously provided by the sensors. It controls the valves of the corresponding hydraulic cylinder in mere fractions of second.

- Works with latest microprocessor technology

- Precise comparison of set point and actual value

- Control of valves for corresponding hydraulic cylinder

Connecting box/Mainfall

The connecting box is the connection point for all sensors active in the system. The mainfall sensor is also integrated into the box: It measures the inclination of the grader on the longitudinal axis.

- Connection point for all active sensors in the system

- Reduced cable quantity ensuring longevity and easy repair

- Integrated main-fall sensor

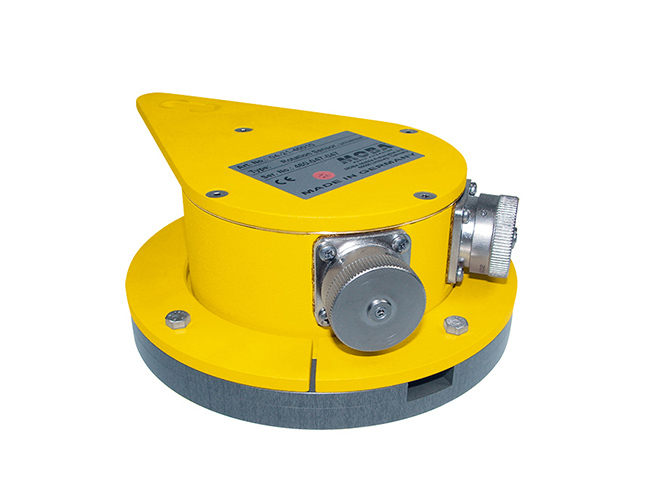

Rotation sensor

This sensor measures the value of the blade rotation. Together with the mainfall sensor, it provides optimum compensation for cross slope.

- Provides optimum compensation for cross slope

- Measures the value of the blade rotation

- Compensation of interference’s

Cross slope sensor

Maintains specified slope values. It records current measurement values for blade slope, vehicle inclination and blade rotation, taking into consideration interfering factors such as acceleration or impacts.

- Dynamic fluid sensor to maintain the cross slope

- Measures the slope of the blade

Proportional hydraulic valve

The hydraulic unit controls the cylinder movements based on signals generated by the controller.

-

-

-

-

-

- Convert signals into motion

- Controls the cylinder movements according to the controller signals

- Ensures that speed of movement is consistent with measured deviation

-

-

-

-

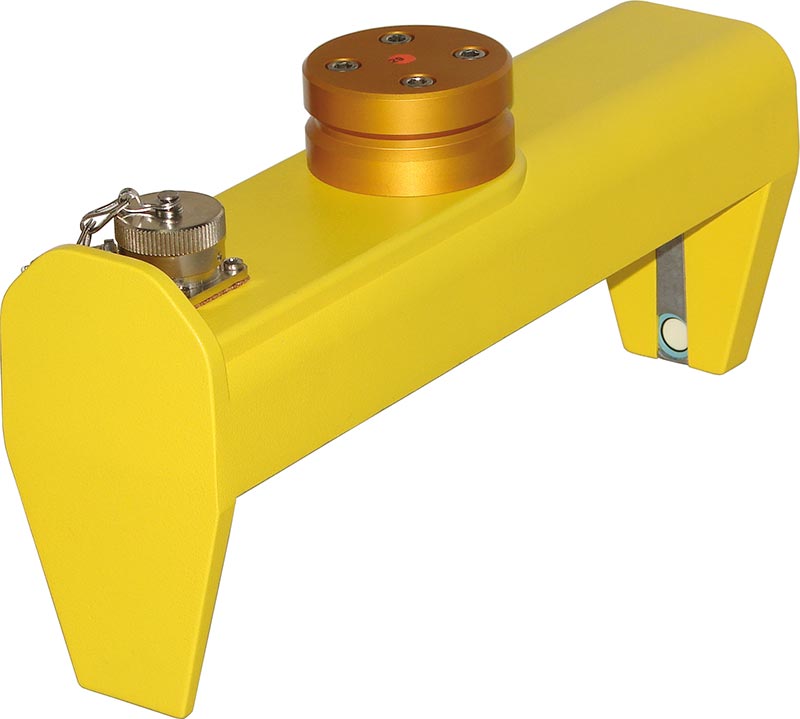

Ultrasonic sensor – Sonic-Ski

The accuracy of the MOBA Sonic-Ski ® is currently unmatched on the market. Altogether five sensors for height measurement plus an additional sensor for temperature compensation allow for an accuracy of ± 2 mm over the sampling width

of 250 mm.

- Five contact-free sensors scan the reference surface

- Extremely precise distance measurement by means of averaging

- Provides virtual level reference

- Real-time temperature compensation

Laser receiver

The LS-3000 laser receiver is a highly precise sensor for grade measurement. It works with all common rotary laser transmitters. Deviations are recorded with millimeter precision in a reception range of 360°.

- Compatible with all common rotating laser transmitters

- Exact height measurement

- Receiving range 360°

- Digital linear detection of the laser beam